Companies dealing with manufacturing and distribution across varied locations must be capable of running their key business processes round the clock. They need to ensure uninterrupted service to customers while managing scalability. During peak periods, they may face challenges caused by network latency or unreliable connections competing for system resources simultaneously.

Regular or periodic maintenance for various regions across different time zones or meeting different scheduling needs may also create challenges. It is crucial for companies to execute their daily mission-critical processes without interruption under such situations. Companies execute their mission-critical warehousing and manufacturing processes seamlessly with cloud and edge scale units.

Cloud and edge scale functionality is offered by the add-ins mentioned below:

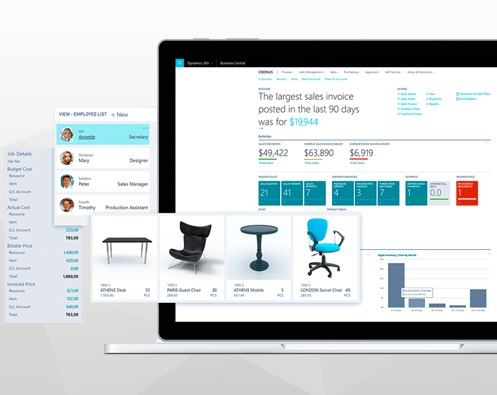

All you need is a Dynamics 365 supply chain management hub and a scale unit deployed with warehouse management workload. This hybrid architecture enables users to distribute manufacturing and warehousing workloads across on-premises and Azure computing infrastructure.

All the scale units are connected to the enterprise-wide supply chain management hub in the cloud. This enables having all the necessary information ready for fulfilling the business requirements. Users can deploy edge or cloud scale units to meet their unique challenges.

Modern business organizations operate with warehouses across regions, in multiple geographical locations, and across different time zones to meet their customers’ demands efficiently. Manufacturing and warehousing facilities are spread out so that they match shipping requirements with global operations. This necessitates a high level of resilience, ensuring availability, scale, and reliability.

This distributed model facilitates interruption-free operations even when disconnected temporarily from the cloud. Especially, companies struggling with connectivity and latency will find this extremely useful when running their operations in remote facilities.

Barcoding in Dynamics 365 advanced warehouse management is an inexpensive, user-friendly, and effective business application that enables users to track a multitude of relevant data from pricing to inventory. Barcoding with GS1 standard eliminates the need for manual information input process and multiple scanning. Dynamics 365 has introduced the ability to scan GS1 barcodes that is a new feature in advanced warehouse.

This simplifies the scanning process in warehouses. Users can now scan the GS1 barcode to instantly retrieve necessary information about a package or product. A single scan provides all the required information accurately. The GS1 is the minimum setup required to use the GS1 barcode standard in Dynamics 365.

By scanning a barcode with GS1 standards, companies can understand crucial information such as a product’s constituent materials, expiry period, location, price, and more.

The visibility and accuracy enable manufacturers, suppliers, distributors, and even end-users to track a product through the supply chain. It facilitates efficient warehouse space management and enables offering products for sale both online and in physical stores. Increased use of GS1 standards is likely to transform the way barcodes are used and help warehouse managers to achieve maximum efficiency.

GS1, the global standard for exchanging data among different organizations, defines the data format and the different types of data that may be encoded. As these barcodes have multiple data elements, a single barcode may include several types of product information such as expiration date, batch, inventory, and much more.

Barcodes enable entities like manufacturers, transport service providers, retailers, and warehouses to automatically identify and track the products and services as they move through the supply chain. Traceability and transparency are crucial in the supply chain. With GS1 barcoding, businesses can achieve transparency throughout the supply chain and gain insights into all the locations where their product stops along the way.

GS1 barcoding provides a framework for interoperable traceability systems of supply chains. This standard provides manufacturing and warehousing organizations with crucial knowledge and key insights into traceability, product content details, inventory, and other helpful information. The details include a product’s processing history, the origin of materials, parts, location, and distribution of the product or service post-delivery.

The serial shipping container code (SSCC), an 18-digit number, is immensely helpful in identifying logistics units. SSCC is often encoded using barcoding, mostly in GS1 format. This facilitates accurate and secure eCommerce transactions.

Global eCommerce enterprises such as Amazon, eBay, and Sam’s club, and services such as Google Shopping require eCommerce companies and warehousing businesses to use GS1 barcoding for accurate identification and prompt delivery of products and services.

GS1 barcoding helps companies of all sizes to accurately identify, sell, and deliver their products. It is being used by logistics majors such as UPS, FedEx, and other multinational businesses.

Modern warehouses must have an effective barcoding system with high-quality scanners that can be connected to the inventory management system, such as Dynamics 365 advanced warehouse management. Cloud and edge scale units provide dedicated capacity for warehouse execution processes, allowing businesses to build resilience into their supply chain.