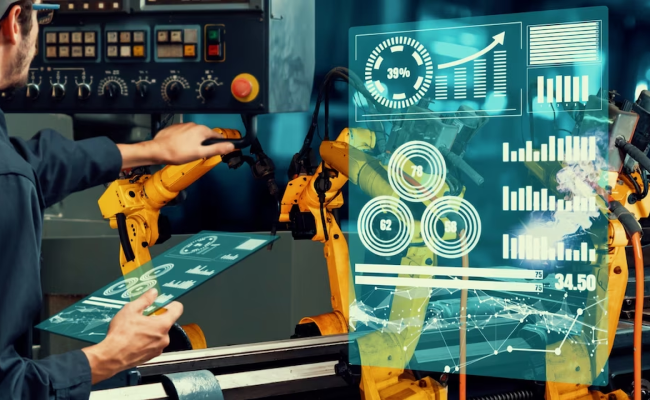

Simplify your global, mixed-mode manufacturing to drive anytime, anywhere production

Oracle Fusion Cloud Manufacturing is an optimized solution powered by AI and IoT

Execute discrete and process manufacturing seamlessly with Oracle Fusion Cloud Manufacturing

Run your shop floor operations more efficiently with Oracle Fusion Cloud Manufacturing- a modern solution that leverages IoT to record and analyze data from your factory operations and converts it into predictive insights to accelerate productivity. Fully integrate your manufacturing solution with other Oracle supply chain and ERP products to unleash intelligent, automated, and connected manufacturing.

Unleash smart manufacturing practices with adaptive intelligence, Internet of Things, and Machine Learning-powered Oracle Fusion Cloud Manufacturing

Discrete Manufacturing

Streamline your production cycle by visually defining production operations. Optimize costs by identifying the underlying factors causing variances and digitally transform your factory operations for modern, lean, and efficient shop-floor processes. Leverage predictive analytics to identify and correct potential issues and maintain regulatory compliance by capturing genealogy for track and trace of products.

Process Manufacturing

Complete a batch with co-products and by-products by visually defining recipes and capitalizing on Oracle’s best-in-class capabilities while controlling batch manufacturing costs. Collect real-time insights to take instant predictive measures and ensure electronic compliance with the integrated solution for Current Good Manufacturing Practices (CGMP)-critical records.

Mixed-Mode Manufacturing

Leverage complete flexibility of production execution and decide on the perfect method for each stage of production. Drive consistency in shop-floor operations by sharing the same dispatch list, quality checks, and production reporting.

Production Scheduling

Leverage work orders and resource availability in real-time to develop high-quality, realistic schedules to increase production throughput while minimizing idle time and changeovers and reducing impediments by offloading to alternate resources. Use intuitive visualizations and simulations to instantly adjust and relieve schedules by resolving issues dynamically. Leverage interactive insights to proactively monitor operations.